Ten Years After the Earthquake—Striving for a Cycle of Ocean-Town-Mountain Activity

This initiative aims for co-existence of ocean-town-mountain and human activity, while establishing a disaster-resistant city that is prepared to provide necessary resources for daily life from within the region. We visited four manufacturers in Minamisanriku who have applied this recycling-based philosophy.

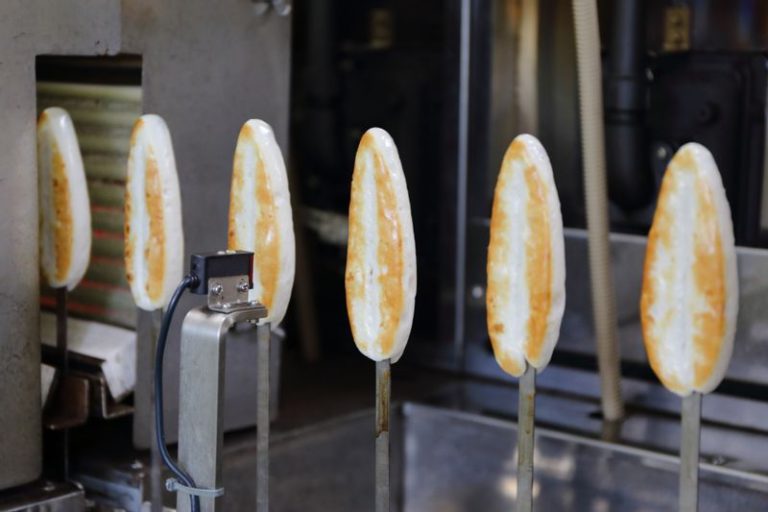

The first-ever room-temperature sasakamaboko, which can be stored at room temperature for 180 days.

Zenya Oikawa, the representative director of Oizen Inc. and sixth-generation head of the Minamisanriku kamaboko shop in business for 140 years, proclaims he is the “No. 1 fan of fish protein in Japan” and actively pursues the potential of kamaboko (fish cakes). Oikawa also developed room-temperature sasakamaboko (fish cakes in shapes of bamboo leaves). Sasakamaboko, a famous delicacy of Miyagi Prefecture, normally needs to be refrigerated and has a shelf life of approximately one week. Room-temperature sasakamaboko has revolutionized these fish cakes, with a shelf life of 180 days at room temperature, without any preservatives added. The product launched in 2019, and was swamped with inquiries and interview requests.

Even from before the earthquake, Oikawa had concerns about how the younger generation was becoming increasingly more detached from kamaboko products. The unprecedented disaster pushed him to create room-temperature sasakama. He teamed up with the Kesennuma kamaboko shop Kanesen to conduct research and development. After much trial and error, a miracle happened when half-heartedly creating a trial product that was practically deemed to be a failure.

“We suddenly were able to make delicious kamaboko that could be stored at room temperature! When we checked the recipe, it was the one containing only salt. When you take a look at the 900-year history of kamaboko manufacturing, the only element that has not changed is adding salt to fish paste. Following the basic principles was ultimately the most powerful and safe route to take,” says Oikawa.

In 2019, he launched Tabisuru Kamaboko (traveling kamaboko), which targeted children and nutritional education, before launching his long-awaited room-temperature sasakamaboko. Kamaboko with a longer shelf life at room temperature also results in less food loss, and allows this kamaboko to be given as souvenirs for people living outside Minamisanriku, and to be used in box lunches.

“We want to be the most interesting kamaboko manufacturer in Japan. We also have a wish to cooperate with other kamaboko makers all over Japan to create space food kamaboko,” says Oikawa. The potential of kamaboko seems to have no limits!

A combination of sea and town delicacies. High-quality Wakame Mutton raised on unused seaweed stems

Wakame seaweed is a famous product of Minamisanriku, but wakame stems, left after the leaves and roots have been used, are too tough for consumption. Katsuya Kanetou, who arrived at Minamisanriku as a volunteer supporting reconstruction efforts, thought of ways to use these stems to create a new Minamisanriku specialty.

“My friend, who has a butcher shop, told me about saltbush lamb, which is an Australian brand of sheep meat that is fed saltbush that grows wild on salty soil. I wondered if something like this could be achieved in Minamisanriku. That’s when the idea of using wakame stems, which are rich in minerals, as livestock feed hit me,” says Kanetou. The Wakame Mutton project was launched at the end of 2012, with cooperation from Miyagi University.

There are currently 160 sheep on Kanetou’s Satoumi Farm. The special feed emits a pleasant acidic fragrance, almost like wine. The moisture from mixing raw wakame stems with pasture grass naturally triggers lactic fermentation. This provides the feed with a shelf life of over a year, and is said to correct the intestinal environment of the sheep to eliminate their distinctive odor. Furthermore, this creates six times more of the umami component, inosinic acid, than usual, creating delicious meat that can be enjoyed with only simple seasonings such as salt and pepper.

Only five sheep are available per month, and the farm’s online shop often sells out of these sheep. The current goal is to ship approximately 120 to 150 sheep annually, and generate enough profits to provide stable employment to those working at the farm.

“Our goal is not sheep but the reconstruction of Minamisanriku. This is just the beginning.”

We may be seeing Wakame Mutton from Minamisanriku become internationally famous one day!

Shiitake Karinto made from small shiitake mushrooms

Seaside is the only shiitake mushroom farm in Minamisanriku. Hiroyuki Takahashi, the executive director of the company, saw the company’s facilities completely destroyed by the tsunami. However, the shiitake sprouting from their harvesting beds pushed him toward rebuilding the company instead.

“The shiitake mushrooms were growing in a positive way, so I decided that I should not give up as well.”

After the shiitake houses were rebuilt and amid harmful rumors following the disaster, Shiitake Karinto (deep-fried dough cookies) was created from smaller shiitake that did not meet product standards. Dried shiitake soaked in water and crushed were mixed with flour, tofu bean curd and rice flour to create a dough, with miso added as the secret ingredient.

“Raw shiitake has an acrid taste, so dried shiitake is used to balance out the mixture. It took almost six months of trial and error to find the best recipe,” says Takahashi. The addictive karinto offers a subtle shiitake fragrance with a sweet and salty taste, making it an instant regional sensation.

“Shiitake farming is more complicated than everyone thinks.” Creating the beds for harvesting shiitake takes 120 days, and growing shiitake while looking out for other unwanted bacteria is very stressful work. Shiitake grows in the spring and autumn, so even if the temperature is below zero outdoors, the harvesting room needs to have a stable temperature and humidity all year round. Shiitake are harvested approximately seven to ten days after the first buds appear. The timing of harvesting shiitake depends entirely on the staff’s skills.

The beds used for growing shiitake become industrial waste after the harvest, so it costs money to dispose of it. That is why Seaside reuses all beds as agricultural compost. It is dried and offered free of charge to farmers in the region. Mixing discarded shiitake beds into farming soil is said to create high-quality soil.

Takahashi maintains his positive stance, stating, “I love how that the remnants of our produce connects us to others elsewhere.”

Growing indigo plants on abandoned fields. Recycling-based Ai-cha

Miku Nakamura, who is originally from Tokyo, lives in an old farmhouse in the Haraikawa settlement, at the foothills of Mt. Tatsuganesan while farming indigo plants without using any agricultural chemicals. Her three-year-old daughter, Rikka, accompanies her to the fields and enjoys catching insects, already showing potential to become a great farmer. Miku’s job is to offer a little touch to things that are no longer used, for further application in the future. Her indigo plant fields were also created by cultivating abandoned farming land.

As a part of the Minamisanriku Biomass Industrial City Concept, Minamisanriku proactively creates liquid fertilizer from collected kitchen refuse. Miku uses this liquid fertilizer to cultivate her indigo plants. She also uses milk spray and beer instead of pesticides. The harvested leaves are dried and stored to create and sell indigo-dyed products or Ai-cha (indigo tea). Although indigo is known for its dyeing properties, it was also traditionally used as a medicinal herb.

According to Miku, the reason for her moving from Tokyo to Minamisanriku was that she was moved by the people who had gone through such a devastating experience, but still had the power to move forward. She wanted to be close to those people.

Within her volunteering activities after the disaster, chance provided her with a job at the Minamisanriku Tourism Association, pushing her decision to move. Currently, she has launched the Dendenmushi Company and centers her activities around her indigo plant field, which started when she worked at the tourism association, along with a project to renovate old farming houses using her expertise in architecture. The reason she named her company dendenmushi (snail) after the indigo field’s archenemy is because she wants to “coexist with nature, which is unrelenting.”

“My ultimate goal is to ensure that Minamisanriku continures to thrive in the future. In addition to disaster reconstruction efforts, there are regional issues such as the low birthrate and aging population, along with vacant houses. I want to do what I can for this town, which I love very much.”

Now it is Miku’s turn to channel her energy into Minamisanriku.

Nature provides blessings to humans, but sometimes creates terrifying experiences. The reason the citizens of Minamisanriku are so strong and gentle may be because they accept nature as it is and are aiming for co-existence. Until the day comes that the activities of each individual become an enormous circle, we will continue to set our sights on the future of the town.

Some photos provided by: Minamisanriku-cho Tourism Association