Bringing New Rice to the Tables: A Rice Mill That Conveys the Thoughts of Producers

Meticulous Rice Milling Process Passed Down from the Previous Generation

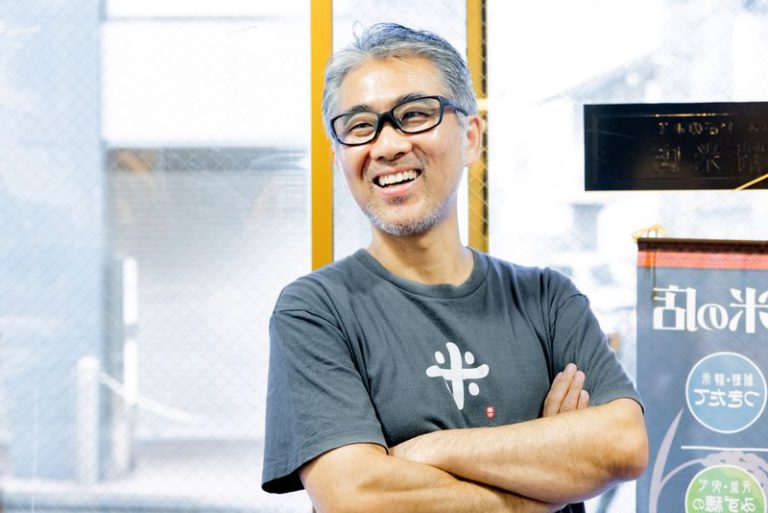

Koike Rice Mill was founded in 1930. Currently, it is managed by four people, including Mr. Koike. The charm of this mill lies in the fact that Mr. Koike procures most of the rice by actually going to the regions where it is grown, which means that he knows the rice farmers in person. One more thing that makes it unique is the rice milling technology that has been passed down from the previous generation.

These days rice milling machines that can mill rice at the touch of a button are commonplace. Contrary to that trend, Koike Rice Mill carefully adjusts the milling process according to the rice condition to maximize the rice’s qualities.

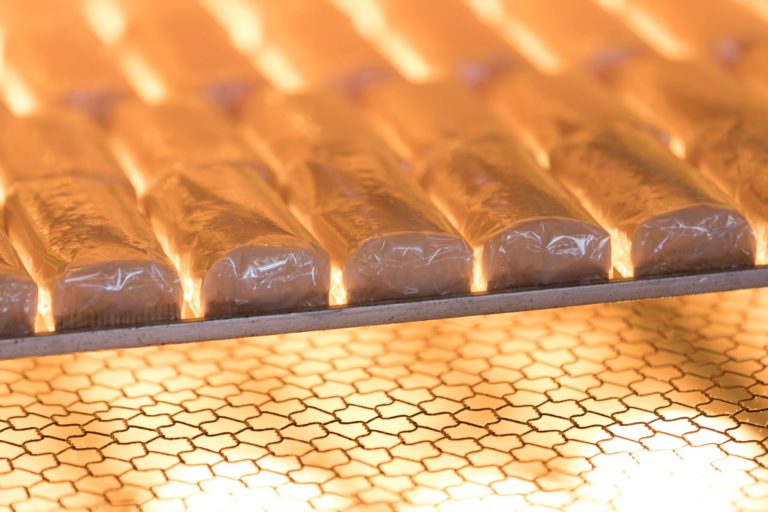

First, unpolished brown rice is mixed in a rice mixing machine. Sometimes they mix different varieties, and sometimes they adjust the taste by mixing the same variety but from different bags since the taste can differ, even across the same variety. Once that step is done, small stones and other impurities are removed from the rice using a destoner machine. Now, the milling process can finally begin.

“To put it simply, rice milling is a process of removing the outer bran layer from the rice. This can be either done by polishing the rice grains against each other using friction or polishing them against grindstones.”

Mr. Koike uses a 30-year-old rice milling machine that he inherited from his father. Its power can be finely adjusted to match the condition of the rice. Apparently, the machine allows him to mill the rice to perfection by fine-tuning the friction strength, the grinding strength, and the rice flow speed.

“Of course, the final effect varies depending on the rice variety as well as the season and the harvest year. I make fine adjustments so that I achieve optimal quality, no matter the rice variety. And that requires making judgments based on the appearance of the rice,” says Mr. Koike.

When milling the rice, Mr. Koike is mindful not to polish the rice too much. The sub-aleurone layer between the starch and the bran layer is the source of the rice’s sweetness and umami. Thus, the secret to bringing out the natural flavor of the rice is to fine-tune the milling process every time to maintain that sub-aleurone layer and keep the rice grains from breaking.

Lastly, the rice is sorted by color using a dedicated machine.

“Rice is an agricultural produce, so there are grains that aren’t perfectly white. Passing it through a color sorting machine helps me separate it by shade and remove the discolored rice grains with a blast of air.”

The rice milled upon fine and careful adjustments like this is then provided to restaurants and homes across Tokyo.

Additionally, Koike Rice Mill offers custom rice blends in accordance with customers’ needs and can mill the rice to order. They are trusted by many dining establishments that are particular about the quality of rice, such as sushi shops, traditional Japanese-style restaurants, and Korean BBQ establishments. Based on his knowledge and experience, Mr. Koike can propose just the perfect type of rice required by professional chefs.

The Diverse Flavors of Rice Born from Local Climates

Shinmai or “new rice” is what Japanese people commonly call the rice that was harvested, milled, and packed around September and October. The flavor of rice obviously depends on the harvest season. We asked if there are also any regional characteristics.

“The same variety of rice can taste differently depending on many aspects, including the region and climate. That being said, the quality varies from year to year, so it’s impossible to define the general characteristics by region,” says Mr. Koike.

The Koshihikari variety of rice is produced nationwide on the one hand, but other varieties have their limited production regions. One reason behind the various regional types of rice is that the rice is a “short-day crop.”

“The characteristic of short-day crops is that they produce grains when the day gets shorter. Let’s take Hokkaido, for example. Due to its high latitude, it isn’t suited for growing the standard varieties of rice. Nanatsuboshi is a special type of rice that was developed to match the amount of sunlight in Hokkaido.”

Five-Star Rice Meister Shares How to Identify a Good-Tasting Rice

Mr. Koike holds the highest rice meister qualification awarded by the Japan Rice Merchants Association, namely “Five-Star Rice Meister.” We asked him to tell us about the common characteristics of good-tasting rice.

“It all comes down to umami. From there, it’s a matter of personal preferences. A certain rice shop owner once told me that rice is like paintings. There’s top-class rice grown with the utmost care. Some of them can be likened to pieces by Van Gogh or Picasso, and whether you like them or not, it depends on your taste.”

Even so, who wouldn’t like to have a taste of the rice approved by a rice specialist?

“Although I can sincerely recommend all varieties that we have on hand, Musubi no Kami from Mie Prefecture is quite unique. It has big rice grains with a bite to them, a moderately light taste, and a faint sweetness. Personally, I like the Nikomaru rice, which is a special variety often seen grown in Shikoku and Kyushu. The Tenku no Sato variety from the town of Motoyama in Kochi Prefecture is grown on beautiful terraced rice paddies.”

Some consumers choose rice based on its production region. Others determine their choice by nutritional value. With the growing focus on health, more and more people are opting for brown rice. But how does the milling process affect the nutritional values of rice?

“The brown rice with the bran left on has the most dietary fiber and it is rich in vitamin E, iron, and minerals. Naturally, the more you polish off the bran, the more of these nutrients get lost.”

On the other hand, brown rice is hard to digest, so it may cause stomach issues for some people. “I’d recommend to start slowly with half-milled rice,” says Mr. Koike.

Rice milling can be done to different degrees, with white rice having 10% of rice removed. You can find 30%, 50%, and 70% rice. The smaller the percentage, the closer the product is to the brown rice. The bigger it is, the whiter the rice.

In order to fully bring out the natural flavor of tasty rice, it needs to be stored and cooked properly. The standard way to store rice is to place it in an airtight container in a cool and dark place right after purchasing it, but the soaking time is crucial as well.

“Giving it time to absorb the water is the trick that allows the umami of rice to shine through. Whether you use a rice pot or a clay pot, it’s important to soak the rice for at least one to two hours. I always let it sit in the water for six hours.”

Conveying the Charm of Rice to as Many People as Possible

It has been 20 years since Mr. Koike inherited the milling technology, the milling machine, and the love for rice from his father. When asked about the recent rice shortage, he says, “Rice farmers have dropped their production due to lower consumption of rice, which is part of the reason behind the shortage. I guess the supply couldn’t keep up with the sudden buying up of rice.”

Mr. Koike says that his goal going forward is to “spark an interest in rice in as many people as possible.” He has been using social media and actively engaging in local events with the aim of conveying the appeal of rice. “It has always been my mission. I will keep up my efforts so that more and more people will want to eat delicious rice,” says Mr. Koike with a smile.

So, Mr. Koike continues to travel around the production regions across Japan and share the appeal of different rice varieties from his rice mill on Omotesando Street.